Ho na le mefuta e mengata eaho lahla, tseo ka tloaelo li arotsoeng ka:

① ho lahla hlobo e tloaelehileng ea lehlabathe, ho kenyeletsoa hlobo ea lehlabathe le metsi, hlobo e omeletseng ea lehlabathe le hlobo ea lehlabathe e thatafatsang lik'hemik'hale.

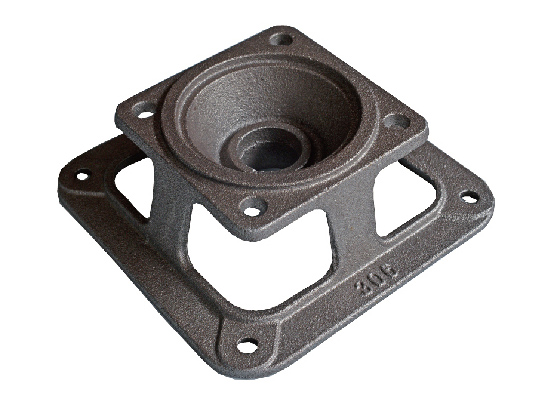

② ho ea ka thepa ea ho bōpa, ho lahla ho khethehileng ho ka aroloa ka mefuta e 'meli: ho lahla ho khethehileng ka lehlabathe la tlhaho le lejoe e le lisebelisoa tse ka sehloohong tsa ho bōptjoa (tse kang ho lahla matsete, ho lahla hlobo ea seretse, ho lahla hlobo ea likhetla ka har'a seboka sa ho lahla, ho lahla khatello e mpe, ho lahla hlobo e feletseng, ho lahla hlobo ea ceramic, joalo-joalo) le ho lahla ho khethehileng ka tšepe e le lisebelisoa tse ka sehloohong tsa ho bōptjoa, joalo-joalo. ho lahlela khatello e tlase, ho lahla centrifugal, joalo-joalo).

Hangata, mokhoa oa ho lahla o kenyelletsa:

① ho lokisa hlobo (setshelo sa ho etsa tšepe ea metsi hore e be e tiileng). Sebopeho sa ho lahla se ka aroloa ka hlobo ea lehlabathe, hlobo ea tšepe, hlobo ea ceramic, hlobo ea letsopa, hlobo ea graphite, joalo-joalo ho ea ka thepa e sebelisoang, 'me e ka aroloa ka hlobo e lahlehang, hlobo e sa feleng le hlobo e sa feleng ho latela palo ea linako tse sebelisoang. Boleng ba ho lahla hlobo ho lokisetsa ke ntlha e ka sehloohong e amang boleng ba li-castings;

② ho qhibiliha le ho tšeloa ha litšepe tse entsoeng. Lisebelisoa tse entsoeng ka tšepe (li-alloys) haholo-holo li kenyelletsa tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe le li-alloys tse se nang ferrous;

③ kalafo le tlhahlobo ea li-castings, ho kenyeletsoa ho tlosoa ha litaba tsa kantle ho mantlha le bokaholimo ba li-castings, ho tlosoa ha gating le riser, ho pshatla le ho sila ha li-burr, burring le li-protrusions tse ling, hammoho le kalafo ea mocheso, sebopeho, kalafo ea thibelo ea mafome le machining a thata.

Ts'ebetso ea ho lahla e ka aroloa likarolo tse tharo tsa motheo, e leng, ho lokisetsa tšepe ea ho lahla, ho lokisetsa hlobo le phekolo ea ho lahla. Cast metal e bolela lisebelisoa tsa tšepe tse sebelisetsoang ho etsa tlhahiso ea ho lahla. Ke motsoako o entsoeng ka karolo ea tšepe e le karolo e ka sehloohong le likarolo tse ling tsa tšepe kapa tse seng tsa tšepe. Ka tloaelo e bitsoa alloy cast, haholo-holo ho kenyelletsa tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe le alloy e se nang ferrous.

JN-FBOHo Thunya Lehlabathe le Otlolohileng, Ho Bopa le ho Hokalla ho arohana ho tsoa hoMochine oa ho Bopa Mabokoseea lihlahisoa tsa JUNENG e na le melemo ea ho thunya lehlabathe le otlolohileng, ho bopa le karohano e otlolohileng. E loketse haholo ho hlahisa li-castings tse sa tšoaneng. Ho ea ka li-castings tse nang le bophahamo bo fapaneng ba hlobo ea lehlabathe, e ka fetola ka mokhoa o sa feleng le ka mokhoa o ke keng oa lekanngoa bophahamo ba ho thunngoa ha lehlabathe la liforomo tsa lehlabathe tse ka holimo le tse tlaase, ho boloka palo ea lehlabathe le sebelisoang, kahoo e fokotsa litšenyehelo tsa tlhahiso.

Metsoalle e hlokang e ka sheba lintlha tse amehang tsa mochini ka lintlha tse latelang tsa ho ikopanya.

Motsamaisi oa Thekiso : zoe

E-mail : zoe@junengmachine.com

Mohala : +86 13030998585

Nako ea poso: Mar-11-2025