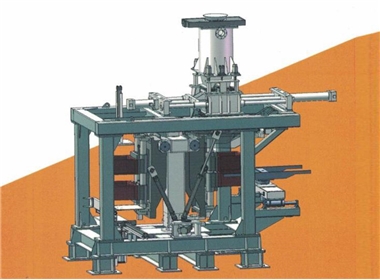

(Double stand sandblasting horizontal parting machine) ke mofuta oa lisebelisoa tse sebelisoang indastering ea ho lahla. Ke mochini oa ho etsa othomathike o sebelisetsoang ho etsa li-castings tsa tšepe, tšepe, aluminium le lisebelisoa tse ling tsa tšepe.

Sesebelisoa se na le likarolo tse latelang:

1. Moralo oa ho ema ka makhetlo a mabeli: Thepa e na le litsi tse peli tsa mosebetsi, tse ka etsang ka nako e le 'ngoe ho tlatsa hlobo, compaction, ente ea seretse le mehato e meng ea ts'ebetso ho ntlafatsa katleho ea tlhahiso.

2. Theknoloji ea Sandblasting: Thepa e sebelisa theknoloji ea sandblasting, e khonang ho fafatsa seretse ka ho lekana ka har'a hlobo ho etsa sebopeho se hlokahalang sa ho lahla.

3. Karohano e otlolohileng: Thepa e nka mokhoa oa ho arohana o otlolohileng ho phethela ts'ebetso ea ho theola le ho pholisa ea ho lahla ka ho bula le ho koala hlobo.

4. Ts'ebetso e ikemetseng: Thepa e na le mokhoa oa ho laola othomathike, o ka hlokomelang ts'ebetso ea othomathike ea ts'ebetso eohle ea tlhahiso, mme e na le ts'ebetso ea ho hlahloba phoso le alamo.

Mochini oa ho arola o karohanoang habeli o emeng oa sandblasting o sebelisoa haholo indastering ea ho lahla 'me o ka hlahisa li-castings tsa mefuta le boholo bo fapaneng, tse loketseng litlhoko tsa tlhahiso le ho lahla tsa boholo bohle.

Mochini oa ho thunya lehlabathe o habeli o na le melemo e latelang:

1. Ntlafatsa katleho ea tlhahiso: sebopeho sa liteishene tse peli se etsa hore thepa e khone ho tlatsa hlobo le ho tšela, ho bula hlobo le ho etsa ts'ebetso ka nako e le 'ngoe, e leng ho ntlafatsang haholo katleho ea tlhahiso. Ka nako e ts'oanang ea ho tšela seteisheneng se seng, seteishene se seng se ka lokisa hlobo, e hlokomelang tlhahiso e tsoelang pele le katleho e phahameng.

2. Boloka litšenyehelo tsa basebetsi: Ka lebaka la moralo oa liteishene tse peli, ha li bapisoa le mochine oa ho thunngoa oa lehlabathe oa setsi se le seng, mochine oa ho thunngoa oa lehlabathe oa makhetlo a mabeli o hloka karolo e fokolang ea mosebetsi. Mokhanni a le mong a ka laola ts'ebetso ea liteishene tse peli ka nako e le 'ngoe, a fokotsa litšenyehelo tsa basebetsi.

3. Taolo e nepahetseng ea boleng ba ho lahla: Mochini oa ho etsa mochini oa ente ea lehlabathe habeli o na le sistimi e tsoetseng pele ea taolo e ikemetseng, e ka laolang ka nepo mocheso, khatello, lebelo la ente ea lehlabathe le likarolo tse ling ho netefatsa boleng bo tsitsitseng ba ho lahla ka 'ngoe. Bokhoni bona bo nepahetseng ba taolo bo thusa ho fokotsa liphoso tsa ho lahlela le ho ntlafatsa sekhahla sa ho tšoaneleha ha sehlahisoa.

4. Ikamahanye le tlhahiso e rarahaneng ea ho lahla: Mochini oa ho etsa lehlabathe oa liteishene tse peli o sebelisa motsoako oa lehlabathe le hlobo ea lehlabathe ho etsa li-castings, tse nang le litšobotsi tsa ho ikamahanya le maemo ka matla. E ka etsa mefuta e fapaneng ea libopeho tse rarahaneng, li-castings tse nepahetseng ho fihlela litlhoko tsa liindasteri tse fapaneng.

5. Ts'ebetso e bonolo le e sireletsehileng: Moqapi oa mochine oa ho thunngoa oa lehlabathe oa makhetlo a mabeli o nahanela boiketlo le polokeho ea mokhanni. Sebopeho sa ts'ebetso ea lisebelisoa se bonolo ebile se hlakile, se bonolo ho se tseba le ho se sebetsa, 'me lisebelisoa tsa polokeho li fanoa ho netefatsa polokeho ea motho ea sebetsang.

Ho akaretsa, mochine oa ho thunya lehlabathe oa makhetlo a mabeli o fetohile thepa ea bohlokoa indastering ea ho lahla ka katleho e phahameng, ho nepahala le botsitso, 'me e sebelisoa haholo ha ho etsoa li-castings tse sa tšoaneng tse rarahaneng.

Nako ea poso: Oct-24-2023