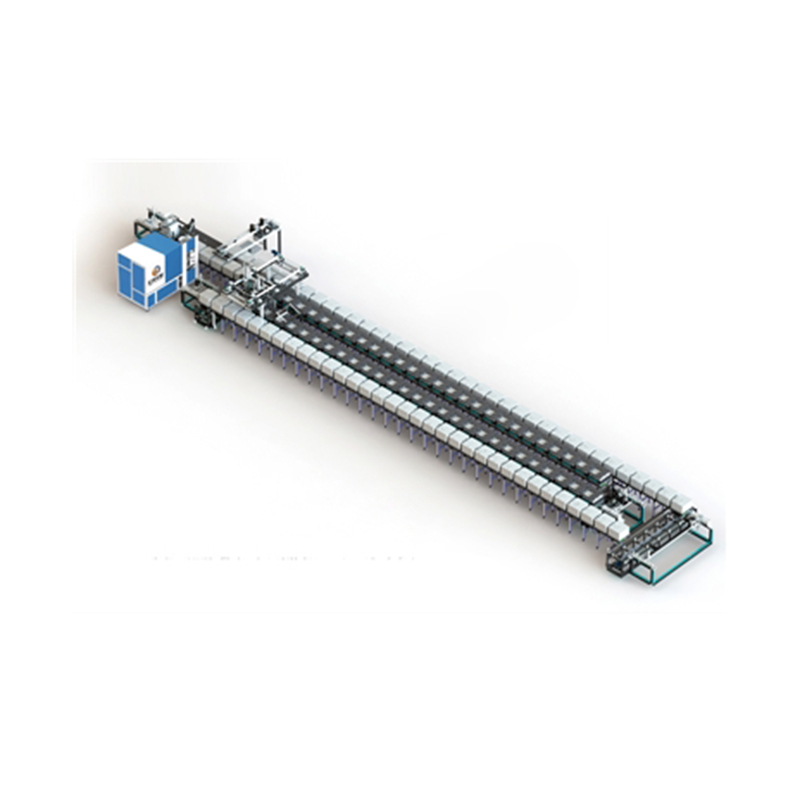

Mochine oa mochini oa ho bopa lehlabathe ke sete e felletseng ea lisebelisoa le ts'ebetso e sebelisoang bakeng sa tlhahiso e boima ea hlobo ea lehlabathe indastering ea ho theha

Mochine oa mochini oa ho bopa lehlabathe ke sete e felletseng ea lisebelisoa le ts'ebetso e sebelisoang bakeng sa tlhahiso e kholo ea hlobo ea lehlabathe indastering ea metheo,

Mochine oa mochini oa mochini oa lehlabathe oa China,

Likaroloana

1. Ts'ebetso e boreleli le e tšepahalang ea hydraulic drive

2. Tlhokahalo e tlase ea basebetsi (basebetsi ba babeli ba ka sebetsa moleng oa kopano)

3. Lipalangoang tsa mohlala oa khokahanyo tse kopaneng li nka sebaka se senyane ho feta litsamaiso tse ling

4. Boemo ba paramethara ea tsamaiso ea ho tšela le ho phalla ho ka kopana le litlhoko tse fapaneng tsa ho tšela

5.Pouring baki le hlobo boima ho etsa bonnete ba boleng ba lehlabathe qeta lihlahisoa

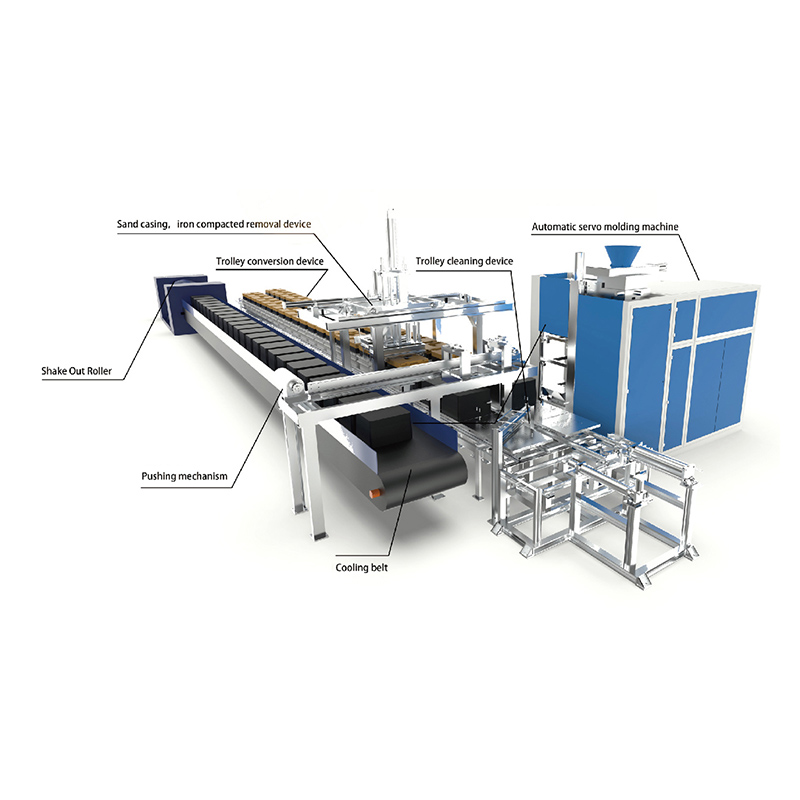

Hlobo le ho Tshela

1. Li-mold tse sa tšeloeng li tla bolokoa holim'a trolley ea mohala oa conveyor

2.Ho lieha ho lahla ha ho ame ts'ebetso ea mochini oa ho bopa

3.Ho latela mosebedisi o hloka ho eketsa kapa ho fokotsa bolelele ba lebanta la conveyor

4.Automatic trolley pushing ho thusa ho tsoela pele ho bōpa

5.Ho eketsoa ha khetho ea ho tšela baki le boima ba hlobo ho ntlafatsa boleng ba ho lahla hlobo

6.Ho tšela ho ka tsoela pele ka hlobo 'me ho tšeloa ho phomola ho netefatsa ho tšeloa ha hlobo eohle.

Setšoantšo sa Feme

Mochini o Itšellang oa ho Tšela

Moulding Line

Mochini oa Mold Molding oa Servo Top and Bottom Shooting Sand Molding Machine

Juneng Mechini

1. Re ba bang ba bahlahisi ba seng bakae ba metjhini e thehiloeng China e kopanyang R&D, moralo, thekiso le tšebeletso.

2. Lihlahisoa tse ka sehloohong tsa k'hamphani ea rona ke mefuta eohle ea mochine oa ho bopa o itekanetseng, mochine o tšelang o itekanetseng le mohala oa kopano oa mohlala.

3. Lisebelisoa tsa rona li tšehetsa tlhahiso ea mefuta eohle ea li-castings tsa tšepe, li-valve, likarolo tsa likoloi, likarolo tsa lipeipi, joalo-joalo Haeba u hloka, ka kopo ikopanye le rona.

4. Khampani e thehile setsi sa tšebeletso ea morao-rao le ho ntlafatsa tsamaiso ea litšebeletso tsa theknoloji. Ka sete e felletseng ea mochini le lisebelisoa tsa ho lahla, boleng bo holimo ebile bo theko e tlase.

Mohala oa mochini oa mochini oa lehlabathe, oo hape o tsejoang e le sistimi ea ho bopa lehlabathe kapa mohala oa tlhahiso ea lehlabathe, ke sete e felletseng ea lisebelisoa le ts'ebetso e sebelisoang bakeng sa tlhahiso ea bongata ba liforomo tsa lehlabathe indastering ea ho theha. Hangata e na le likarolo tse latelang:

Mohala oa mochini oa mochini oa lehlabathe, oo hape o tsejoang e le sistimi ea ho bopa lehlabathe kapa mohala oa tlhahiso ea lehlabathe, ke sete e felletseng ea lisebelisoa le ts'ebetso e sebelisoang bakeng sa tlhahiso ea bongata ba liforomo tsa lehlabathe indastering ea ho theha. Hangata e na le likarolo tse latelang:

1. Sisteme ea ho lokisa lehlabathe: Sistimi ena e kenyelletsa ho lokisa lehlabathe ka ho kopanya lehlabathe le li-bonding agents( tse kang letsopa kapa resin) le li-additives. E ka kenyelletsa li-silo tsa polokelo ea lehlabathe, lisebelisoa tsa ho kopanya lehlabathe, le lisebelisoa tsa ho lokisa lehlabathe.

2. Mokhoa oa ho Etsa Mold: Mokhoa oa ho etsa hlobo o kenyelletsa ho theha hlobo ea lehlabathe ho sebelisa mekhoa kapa mabokose a mantlha. E kenyelletsa kopano ea hlobo, paterone kapa ho tsamaisana ha lebokose la mantlha, le compaction ea lehlabathe. Sena se ka etsoa ka letsoho kapa ka mochini o bopang o ikemetseng.

3. Mechini ea ho Bopa: Mocheng oa mochini oa ho bopa lehlabathe, mefuta e fapaneng ea mochini oa ho bopa e sebelisoa ho hlahisa hlobo ea lehlabathe. Ho na le mefuta e 'maloa ea metjhini e bopang, ho kenyelletsa le metjhini e bopang e se nang botlolo, metjhini e bopang ea botlolo, le metjhini e bopang e ikemetseng.

4. Mokhoa oa ho tšela lehlabathe: Hang ha hlobo ea lehlabathe e lokisitsoe, mokhoa oa ho tšela o sebelisetsoa ho kenya tšepe e qhibilihisitsoeng ka har'a hlobo. Sistimi ena e kenyelletsa lilae, likopi tse tšelang, limathi, le lits'ebetso tsa ho kenya liheke ho netefatsa phallo e ntle le e laoloang ea tšepe e qhibilihisitsoeng.

5. Cooling le Shakeout System: Ka mor'a ho tiisa, li-castings li pholile ebe li tlosoa hlobo. Sistimi ena hangata e kenyelletsa lisebelisoa tsa shakeout kapa litafole tsa vibratory ho arola li-castings ho tsoa ho hlobo ea lehlabathe.

6. Mokhoa oa ho tsosolosa lehlabathe: Lehlabathe le sebelisitsoeng mosebetsing oa ho bōpa le hloka ho khutlisetsoa morao le ho sebelisoa hape ho fokotsa litšila le litšenyehelo. Lisebelisoa tsa ho lokisa lehlabathe li sebelisoa ho tlosa se tlamang se setseng lehlabatheng le sebelisitsoeng, ho lumella hore le sebelisoe hape bakeng sa tšebeliso ea nako e tlang.

7. Tlhokomelo ea Boleng le Tlhahlobo: Ho pholletsa le mohala oa mochine oa ho bōpa lehlabathe, ho laola boleng le mekhoa ea ho hlahloba ho netefatsa hore li-castings li finyella litekanyetso le litekanyetso tse hlokahalang. Sena se kenyelletsa tlhahlobo ea litekanyo, ho lemoha mefokolo, le tlhahlobo ea bokaholimo.

Mohala oa mochini oa ho etsa lehlabathe o etselitsoe ho tsamaisa le ho iketsetsa ts'ebetso eohle ea ho lahla lehlabathe, ho ntlafatsa tlhahiso, boleng le katleho. E ka etsoa ka mokhoa o ikhethileng ho latela litlhoko tse khethehileng tsa foundry le mofuta oa li-castings tse hlahisoang.